As an example, in 2020, the FDA introduced that some prescription drugs had been contaminated which has a ‘potential human carcinogen known as NMDA.’ This occurred due to the fact there was an absence of controls to take care of an aseptic ecosystem.

Your queries, although not your e mail information is going to be shared with OpenAI and retained for 30 times in accordance with their privacy rules. Make sure you never talk to concerns that use delicate or confidential details. Read the entire Conditions & Situations.

Purchasing Liquid bottle filling equipment might have a profound optimistic effect on pharmaceutical organizations, resulting in a noteworthy Raise in their Over-all functionality.

Despite the troubles associated with keeping aseptic problems to the manufacture of these novel biologics, these products are remarkably liable to microbial contamination mainly because of the manual manipulations linked to their manufacturing.

An entire, on-likely servicing application ought to be made and applied. Issues to become particularly coated in the maintenance program ought to include those items listed under Tools Qualification. Additionally, assessment and alternative of elastomeric seals, as well as affliction of molds, dies and pins really should be monitored. The program relates to all supporting gear and devices as well.

In danger assessment, danger identification scenarios might be either utilized prospectively or retrospectively [16]. This paper will work on a future scenario to find out what can go Completely wrong in the procedure/technique and its influence on the caliber of products and/or client protection. The key target is to determine a situation review symbolizing a normal manufacturing approach and carry out the chance evaluation.

Assumes other duties and duties, as needed, throughout the Device Dose / Multi Dose Office, in order to supply the essential assist to be sure adherence to the output timetable

I can revoke my consent Anytime with impact for the future by sending an e-mail to unsubscribe@sartorius.com or by clicking over the "unsubscribe" website link in e-mails I have been given.

A well-liked here online platform guide by pharmaceutical professionals to improve-up pharmaceutical gurus with scientific and complex information.

A notable innovation in this area is ApiJect's BFS container style, which introduces one of a kind attributes that further more enhance the security and performance of pharmaceutical packaging.

The volume of containers used for media fills must be enough to permit a sound evaluation. For small batches the number of containers for media fills should really no less than equal dimensions of item batch.

Additionally, the report explores the rational for not utilizing PUPSIT due to the worry “that the contamination/product deterioration risk associated with undertaking PUPSIT could enormously outweigh the risk of products contamination on account of the masking result. check here To test a filter that has been sterilized by present-day signifies, the sterile filtrate facet with the sterilized filter needs to be under atmospheric strain, requiring a fluid pathway to eliminate any wetting agent. The exposure from the downstream portions on the sterile products transportation line poses a danger to keeping the sterility of the filtered merchandise.

Sterile filling and aseptic filling undergo different microbial avoidance procedures. The sterile fill/finish course of action is about sterilizing the drug formulations, containers, and generation natural environment to destroy microorganisms.

This automated system allows for the successful and aseptic creation of these containers, minimizing the risk of contamination and making certain the security and high quality of the ultimate products.

Neve Campbell Then & Now!

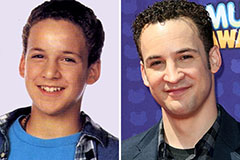

Neve Campbell Then & Now! Ben Savage Then & Now!

Ben Savage Then & Now! Kirk Cameron Then & Now!

Kirk Cameron Then & Now! Ashley Johnson Then & Now!

Ashley Johnson Then & Now! Naomi Grossman Then & Now!

Naomi Grossman Then & Now!